Hollow core fibers (HCFs) are transforming optical communications with their low latency, high transmission speeds, and reduced nonlinearity. But their unique structure also introduces new challenges, especially in the cleaving process.

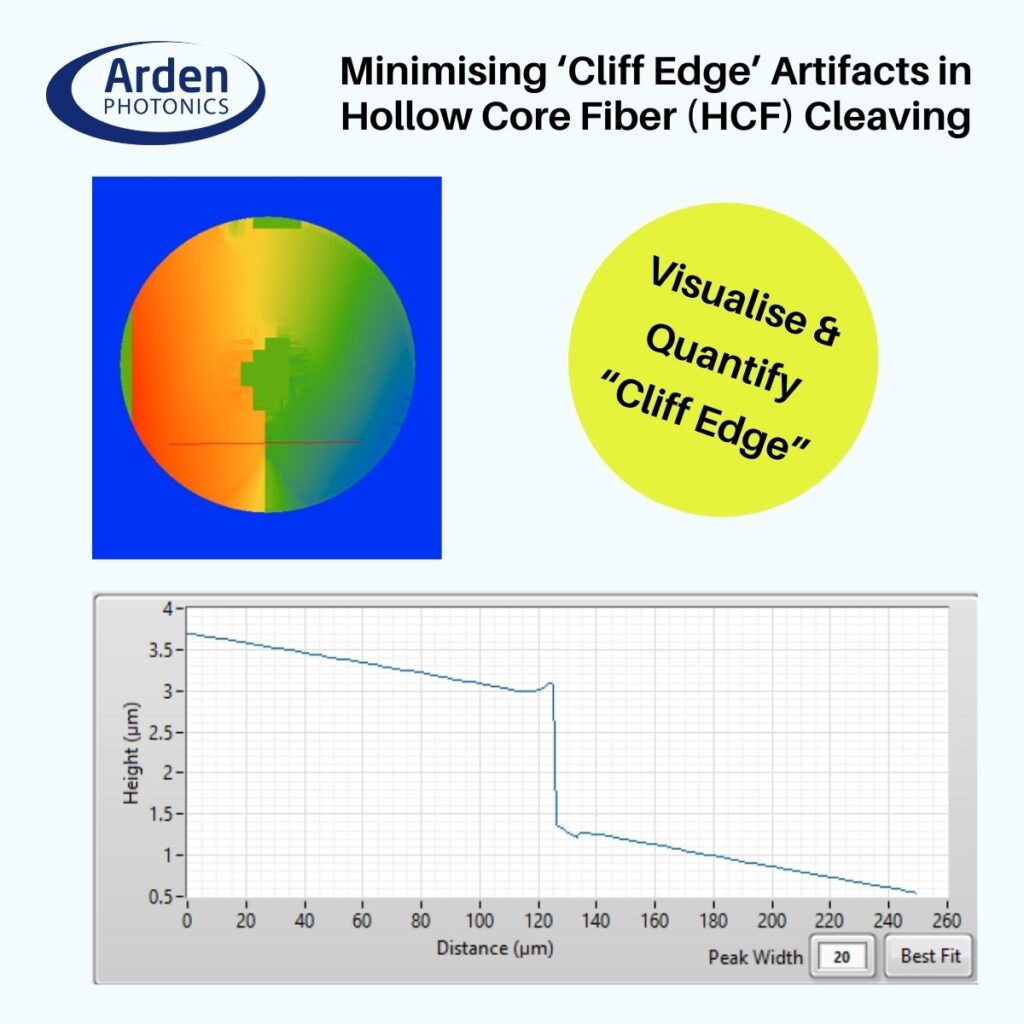

Traditional cleaving methods can create “cliff edge” artifacts, the jagged or uneven faces which lead to higher loss and poor splicing quality. These defects have been difficult to measure due to HCFs’ discontinuous reflection patterns.

Arden’s Interferometer VFI series has been designed to tackle these challenges:

- Advanced sampling algorithms for clear, stable measurements

- 2D & 3D visualisation to map and quantify ‘cliff edge’ artifacts

- Actionable data for optimising cleaving and minimising losses

The VFI series enables HCF manufacturers to achieve higher performance, lower loss, and more reliable splicing for advanced photonic applications.

To learn more, please read the full white paper here, or get in touch with us.