A Great Day Exploring Hollow-core Fiber Measurement at the University of Southampton

Last week, we had the pleasure of attending a technical sharing session at the University of Southampton’s Optoelectronics Research Centre,

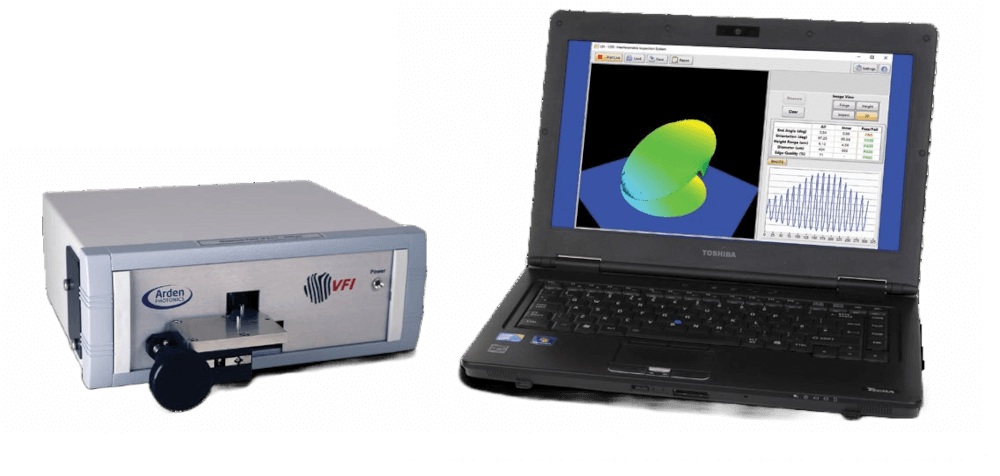

The VFI series are Fiber End-Face Inspection Interferometers for quickly checking End-Face quality on fibers from 125 to 2000 µm in diameter.

The VFI is an interferometric inspection system specifically designed for checking the surface quality and flatness of your cleaved or polished fibers. Users can view their fibers in a range of different views, both in 2D and 3D, allowing the users to get a full understanding of their cleaving or polishing process.

The VFI interferometer measure most standard and specialty fibers including PM fiber and hollow core fiber. It has proven itself in Research, Production and QA over and over and the feedback we get from users indicates that they value these features:

The VFI interferometer has proven itself in Research, Production and QA over and over and is widely used in the following applications:

Last week, we had the pleasure of attending a technical sharing session at the University of Southampton’s Optoelectronics Research Centre,

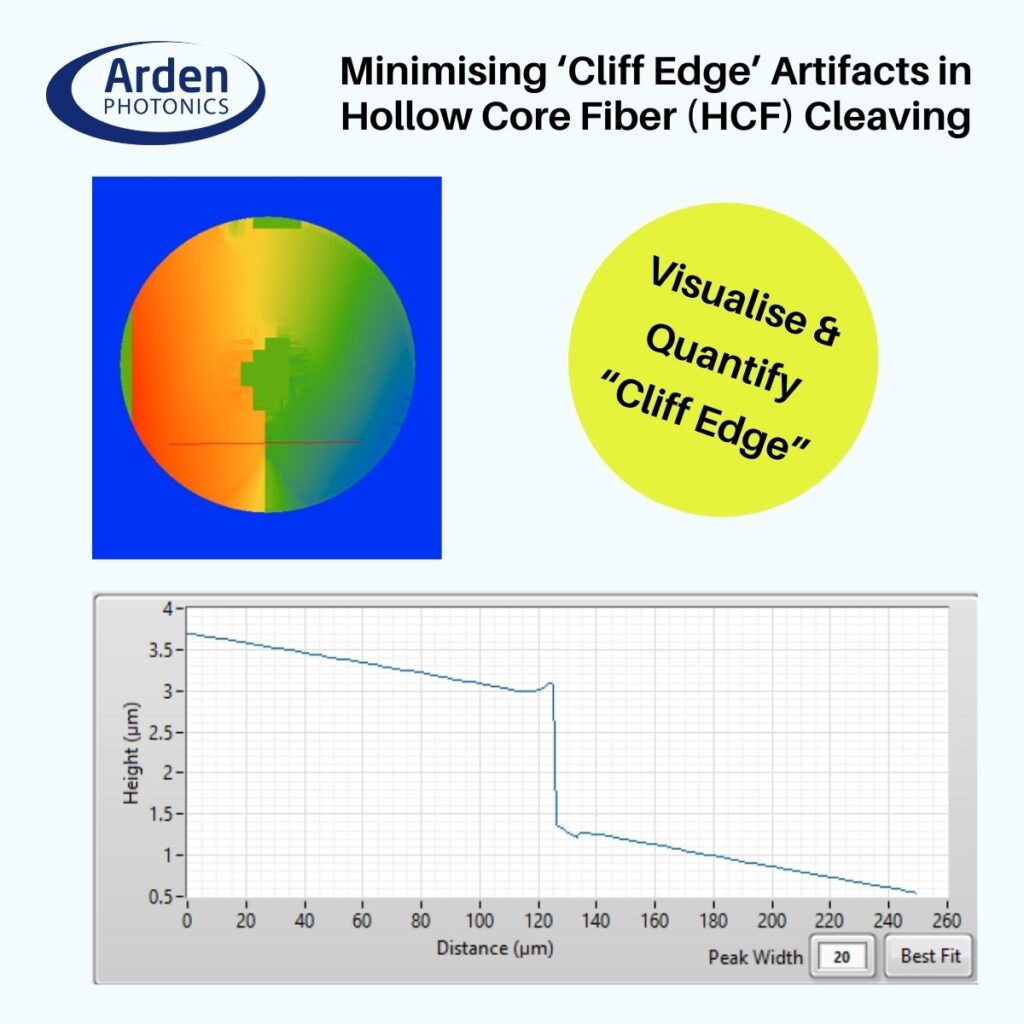

Hollow core fibers (HCFs) are transforming optical communications with their low latency, high transmission speeds, and reduced nonlinearity. But their

In April 1881, Albert Abraham Michelson used his interferometer to try to measure Earth’s velocity. Since then, interferometry has been